The Transformative Role of AI in Manufacturing and Logistics

The Transformative Role of AI in Manufacturing and Logistics

Introduction

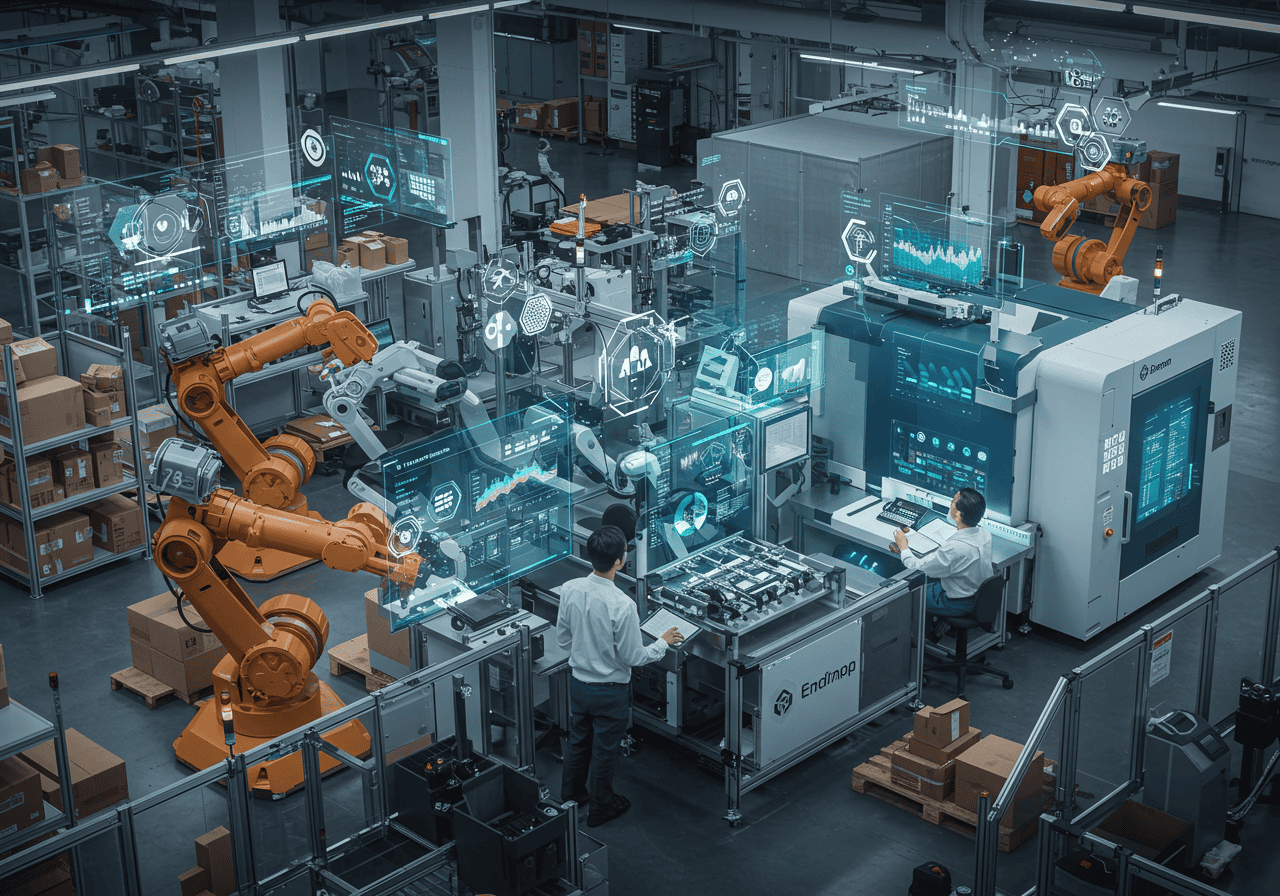

Imagine a world where machines anticipate issues before they occur, and logistics networks operate seamlessly with real-time data. It sounds like something out of a sci-fi flick, doesn’t it? Well, buckle up, because we’re living in that world, thanks to artificial intelligence (AI). The integration of AI technologies in manufacturing and logistics is not just the latest buzzword; it’s a genuine game-changer. These industries, faced with relentless demand and fierce competition, are finding AI to be the secret sauce they’ve been searching for. This article explores the transformative role of AI in manufacturing and logistics, focusing on how it enhances operational efficiency, reduces costs, and improves predictive capabilities, ultimately shaping the future of these sectors.

Overview of AI Technologies Relevant to Manufacturing and Logistics

The rise of AI has introduced some exciting technologies that are particularly useful in manufacturing and logistics. Let’s unpack a few of these innovations.

Key AI Technologies in Use

- Machine Learning: This impressive branch of AI isn’t just a fancy term thrown around in tech meetings. Machine learning is making waves by enabling predictive maintenance. Picture this: machines that can sense wear and tear before they break down. This capability dramatically enhances operational efficiency and keeps productivity humming along nicely. Industries are discovering that by leveraging machine learning, they can avoid costly downtimes and keep everything running smoothly.

- Robotics: If you’ve ever seen a factory floor buzzing with robots, you know these machines are extraordinary. Robotics, enhanced with AI, can automate repetitive tasks that humans used to tackle. This results in fewer mistakes and increased throughput. Imagine an assembly line where robots take over tasks like assembling parts, freeing up human workers for more complex, creative challenges. It’s like giving the assembly line a caffeine boost!

- Internet of Things (IoT): The buzz phrase of the decade! While you might think IoT is all about connecting smart fridges, it’s also revolutionizing logistics. With IoT devices, supply chains gain visibility through real-time analytics. This means companies can keep a finger on the pulse of their inventory and make informed decisions faster than ever. The interconnected devices work in tandem to enhance decision-making, making logistics not just smart, but genius!

Case Studies Demonstrating Successful AI Implementation

Understanding how businesses adopt AI can be enlightening. Case studies often show the practical side of theory in action.

Amazon’s Intelligent Supply Chain

Amazon has set the gold standard for AI integration in logistics. Their operation utilizes advanced algorithms for demand forecasting that would make even the most seasoned analysts stand up and applaud. By predicting what products will be in demand, Amazon smartly optimizes its routing, leading to significant operational efficiencies. So, next time you receive that prime delivery in record time, remember – it’s not just luck; it’s AI at work.

This system has cemented their position at the forefront of e-commerce logistics and serves as a blueprint for companies aiming to enhance their own supply chains. For more insights into Amazon’s strategy, you can explore CDO Times’ detailed overview.

Predictive Maintenance Success

Now, let’s turn our attention to another area: predictive maintenance within the manufacturing sector. Take, for example, a manufacturing firm that enhanced its equipment reliability by a staggering 20%. How? By utilizing AI-driven predictive analytics. This firm could pinpoint when machinery required maintenance before it broke down, minimizing downtime and keeping operations smooth. Talk about efficiency! This success shows just how powerful the right tools can be when they work seamlessly in the background.

Challenges and Considerations When Integrating AI Systems

Despite all the shiny benefits, integrating AI isn’t a walk in the park. Just like that cheerful robot on your factory floor, there are a few hiccups that need addressing.

Implementation Hurdles

- High Costs: Let’s face it, investing in AI technology isn’t cheap. The initial capital needed for AI systems can be prohibitive. Companies sometimes hesitate because they fear the hefty price tag that comes along with implementing cutting-edge tech. While the long-term gains can outweigh the costs, that initial investment can feel daunting.

- Data Quality: Here’s where things get twisty. AI thrives on data. The more accurate and high-quality the data, the better the AI performs. However, many companies struggle with data quality, especially those trying to integrate new systems with legacy technologies. Clean data, ensuring accuracy, and making system decisions based on poor data can lead to pitfalls that are best avoided.

Workforce Impact

- Job Displacement Concerns: The topic of automation often evokes fears about job loss. While it’s true that some roles may fade away, replaced by AI-infused processes, the flip side is that new, skilled roles can emerge. Companies need to focus on re-skilling employees who may find their jobs changing rather than disappearing altogether.

- Training Needs: The call for upskilling cannot be overemphasized. Organizations must invest in retraining their workforce to prepare them for new technologies. After all, getting humans and AI to work together harmoniously might be the greatest challenge of all!

Future Trends of AI in Manufacturing and Logistics

As AI continues to evolve, so too does its application in manufacturing and logistics. Here are some trends to keep an eye on.

Shifts Toward Automation

Predictions suggest that by 2025, nearly half of supply chain organizations will invest significantly in AI solutions. What’s driving this trend? The desire for real-time insights is at the forefront. AI systems will enable companies to react to supply chain disruptions in quick, clever ways—think of it as having a safety net that keeps companies from falling hard.

Evolving AI Management

The future includes AI-managed supply chains. Businesses are beginning to harness advanced analytics and data-driven decision-making. As organizations embrace this, staying adaptable becomes essential. Flexibility in AI strategies will separate the industry leaders from those trailing behind. The ability to pivot and reassess strategies as technology changes is critical to survival.

Strategies for Small and Medium Enterprises to Adopt AI Tools

Not all businesses have the hefty budgets of giants like Amazon. Thankfully, there are strategies available specifically tailored for small and medium enterprises aimed at incorporating AI.

Starting Small

Pilot projects can be a small business’s best friend. By focusing on specific areas like inventory management or customer service to test AI effectiveness, businesses can gauge return on investment without diving into the deep end. Setting clear performance metrics will also help assess whether the pilot is a success or something best left on the shelf.

Cost-effective Solutions

- Cloud-based AI Services: With many features available in cloud-based formats, SMEs can access advanced technologies without breaking the bank. Subscribing to AI services allows small businesses to utilize AI efficiently, akin to having a tech-savvy partner working behind the scenes.

- Partnerships and Collaborations: Teaming up with firms specializing in AI can be a lifeline. SMEs can leverage these partnerships for expertise and resources while sharing costs. Collaborating with tech firms on joint ventures could be the exciting turn of events a small business needs to embrace AI effectively.

Conclusion

AI is not just reshaping the future of manufacturing and logistics; it’s simplifying operations and increasing productivity in ways we’ve never seen before. Yes, challenges like costs and workforce impacts are real, yet the upside is undeniable with thoughtful approaches.

Embracing AI is about more than just keeping pace with technological advancements. It’s about leading transformation in the industry. Businesses that invest in AI today are likely to find themselves at the forefront of innovation tomorrow.

Start exploring AI solutions tailored for your operations and consider launching small pilot initiatives. These could serve as the first stepping stones toward larger transformational changes within your organization.

For more information on the latest manufacturing trends, check out our post on Future Manufacturing Innovations.

Share this content:

Post Comment